Class Project

|

|

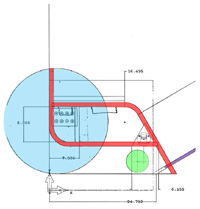

| wheel frame caster footrest Return to India Chair HOME |

|

Welding and Brazing

The frame was tack welded together in a wooden jig using a MIG (metal inert gas) welder. This type of welder uses a self-fed wire as a filler metal. In the welding process, the base metal of the parts being joined is actually melted and the filler wire adds extra material. Once tack welded, the frame joints were all brazed together.

Brazing is a process much like soldering in which the base metal does not melt. The filler material, in this case is an alloy of silver and brass.

The base material is heated and the filler material touched to it. The filler metal flows by what is called capillary action through the joint and makes a metallurgical bond with the base metal.

Brazing was chosen because it is less toxic than welding and it requires no special equipment other than a torch to heat the materials being joined. It is also a more forgiving technology where welding requires significanlty more expertise to achieve good strong joints.